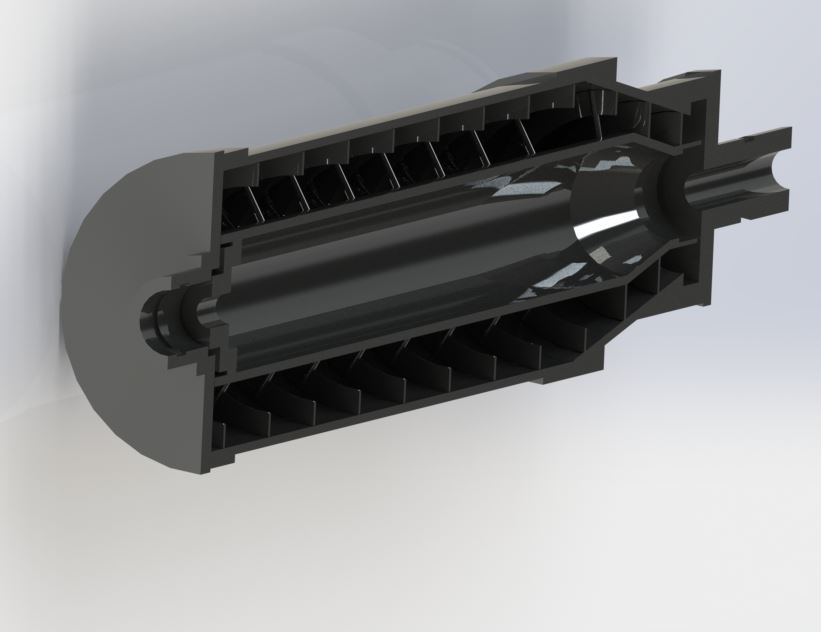

The production of bioethanol has increased significantly in recent years, with modern technology increasing yields during the production process. Stillage is a ‘syrup-like’ byproduct that is distilled from the ethanol after the fermentation process. Animal feed can be extracted from the stillage through the use of decanters that separate the fluid and suspended solids through the use of centripetal forces generated by its rotation. The decanters are routinely washed using water to remove residue that aggregates.

This case study presents an analysis performed on a decanter where concerns had been raised that the sudden cooling of the decanter due to a cold water wash were relieving the bearing interference fits.

The production of bioethanol has increased significantly in recent years, with modern technology increasing yields during the production process. Stillage is a ‘syrup-like’ byproduct that is distilled from the ethanol after the fermentation process. Animal feed can be extracted from the stillage through the use of decanters that separate the fluid and suspended solids through the use of centripetal forces generated by its rotation. The decanters are routinely washed using water to remove residue that aggregates.

This case study presents an analysis performed on a decanter where concerns had been raised that the sudden cooling of the decanter due to a cold water wash were relieving the bearing interference fits.

The decanters normally operate with whole stillage entering at 85°C at a rate of 70 tonnes/hour. The fluid and suspended solids are separated at 2700 rpm. Once every nine days high speed water washing is instigated to clean the bowl and scroll assemblies. Water at 15-20°C is introduced through the feed pipe at 40 m3/hour with the bowl running at 2500 rpm for 30 minutes.

DC White Consulting Engineers were commissioned to examine whether sudden cooling as a result of the cold water wash was relieving the interference fit between the bowl shaft and the inner race of the main bearings. Thereby causing the inner races to slip and rotate during operation. A finite element analysis approach was adopted to establish if this was the case and if so what the optimal temperature for the wash would be.

The decanters normally operate with whole stillage entering at 85°C at a rate of 70 tonnes/hour. The fluid and suspended solids are separated at 2700 rpm. Once every nine days high speed water washing is instigated to clean the bowl and scroll assemblies. Water at 15-20°C is introduced through the feed pipe at 40 m3/hour with the bowl running at 2500 rpm for 30 minutes.

DC White Consulting Engineers were commissioned to examine whether sudden cooling as a result of the cold water wash was relieving the interference fit between the bowl shaft and the inner race of the main bearings. Thereby causing the inner races to slip and rotate during operation. A finite element analysis approach was adopted to establish if this was the case and if so what the optimal temperature for the wash would be.

With the thermal analysis essentially being a two dimensional problem a radial segment of the decanter was used to proceed with analysis.

With the thermal analysis essentially being a two dimensional problem a radial segment of the decanter was used to proceed with analysis.

Transient thermal studies were performed with the appropriate boundary conditions such as the convective heat transfer coefficients and heat generated by the bearings to ascertain the temperatures at the bearing/shaft interfaces.

Transient thermal studies were performed with the appropriate boundary conditions such as the convective heat transfer coefficients and heat generated by the bearings to ascertain the temperatures at the bearing/shaft interfaces.

The contraction of the shaft due to the cold wash was then computed from the finite element analysis to determine if it would relieve the 15 microns interference fit. The cold wash was deemed to be problematic at the feed end and further thermal studies were performed to derive an optimal temperature of 50 °C.

The contraction of the shaft due to the cold wash was then computed from the finite element analysis to determine if it would relieve the 15 microns interference fit. The cold wash was deemed to be problematic at the feed end and further thermal studies were performed to derive an optimal temperature of 50 °C.

The consequences of temperature changes in mechanical devices can have serious implications on its mechanical behaviour as well as production efficiency. DC White regularly have to resolve such problems in the power plant and process industries. Such issues addressed include establishing temperature limits for heat exchangers and the assessment of fatigue damage on pipelines. The most appropriate and cost-effective solution is implemented in every case ranging from a straightforward hand calculation to a more refined CFD (Computational Fluid Dynamics) analysis.

The consequences of temperature changes in mechanical devices can have serious implications on its mechanical behaviour as well as production efficiency. DC White regularly have to resolve such problems in the power plant and process industries. Such issues addressed include establishing temperature limits for heat exchangers and the assessment of fatigue damage on pipelines. The most appropriate and cost-effective solution is implemented in every case ranging from a straightforward hand calculation to a more refined CFD (Computational Fluid Dynamics) analysis.