Our extensive knowledge of vibration problems has enabled us to aid our client, Cristal Global, in many ways. Our early work made us realise that the support structure was in trouble because of the continuous vibration, so we suggested that the vessel support be totally redesigned.

Our extensive knowledge of vibration problems has enabled us to aid our client, Cristal Global, in many ways. Our early work made us realise that the support structure was in trouble because of the continuous vibration, so we suggested that the vessel support be totally redesigned.

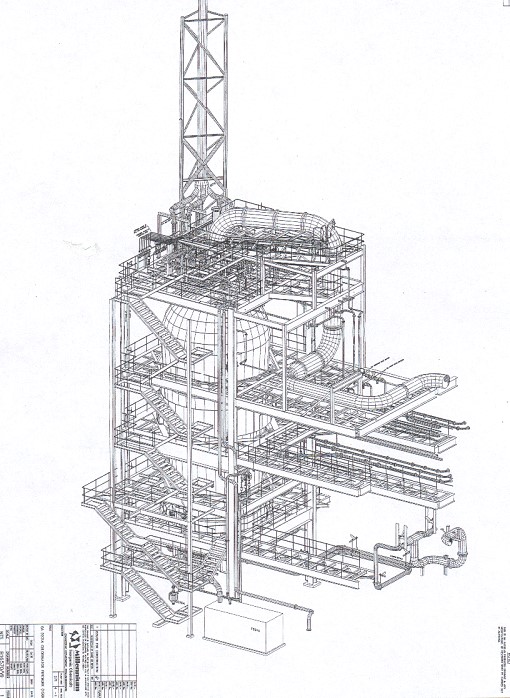

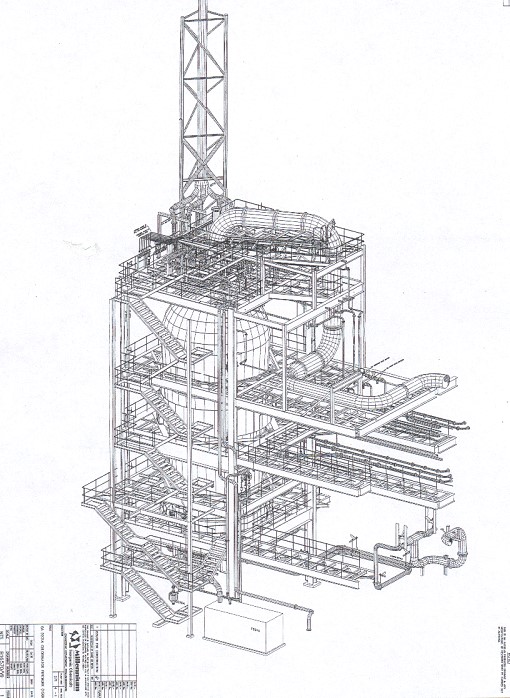

This happened to coincide with a decision to replace the old reactors, so we could start with a blank sheet of paper. We treated the structure and the reactors as a whole and working closely with the steel-work designers we developed a building which has increased the mean time between failures from 4 hours on the old plant to 14 months.

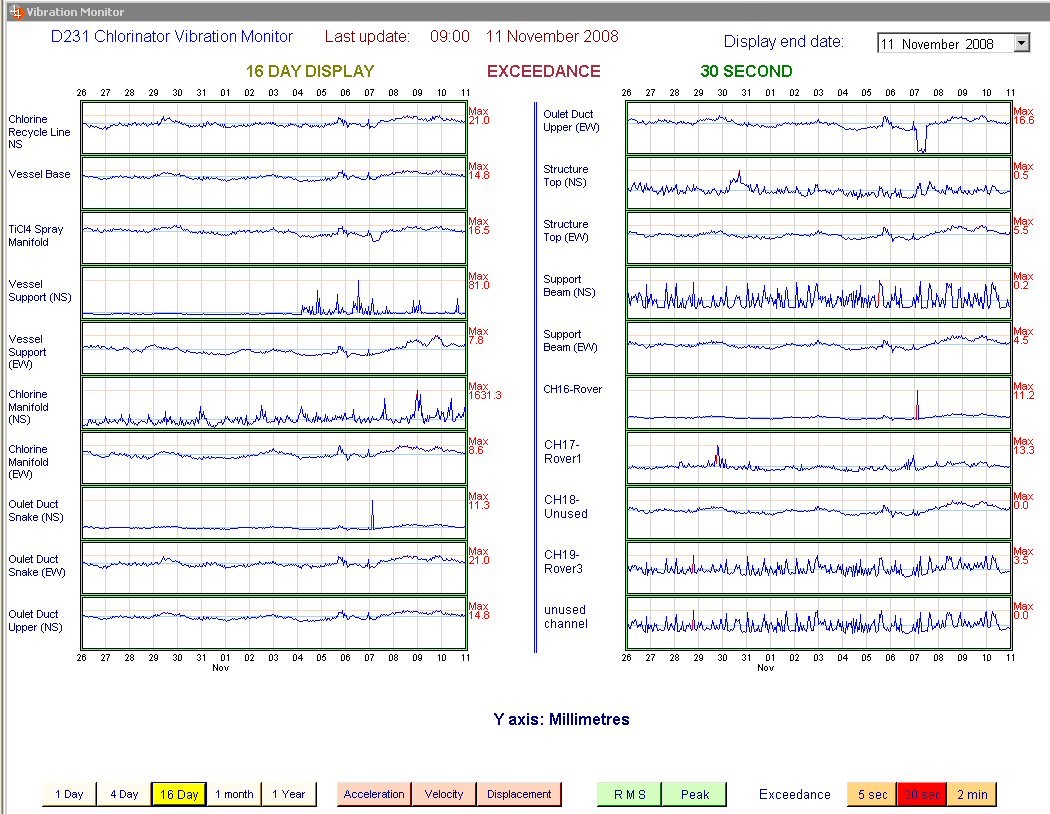

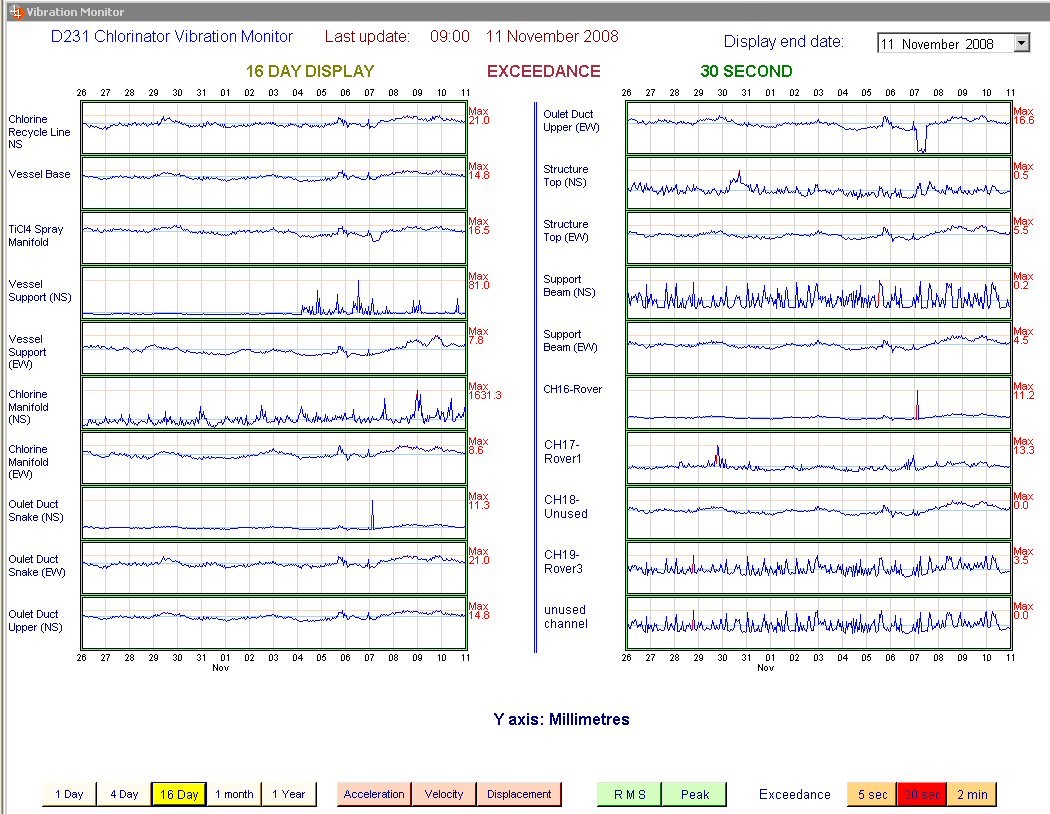

Because of the novelty of this system, we were asked to install vibration monitoring equipment. Now, vibrations are continuously monitored at discrete points on the vessel, the building and on critical sections of pipework. Signals are fed to a signal-processing computer and then onto the plant’s overall digital monitoring system.

This happened to coincide with a decision to replace the old reactors, so we could start with a blank sheet of paper. We treated the structure and the reactors as a whole and working closely with the steel-work designers we developed a building which has increased the mean time between failures from 4 hours on the old plant to 14 months.

Because of the novelty of this system, we were asked to install vibration monitoring equipment. Now, vibrations are continuously monitored at discrete points on the vessel, the building and on critical sections of pipework. Signals are fed to a signal-processing computer and then onto the plant’s overall digital monitoring system.