FEA Thermal Expansion Analysis and Assessment

- A clear and deep understanding of thermal engineering theory and the issues resulting from thermal expansion

- Many collective decades of experience in thermal designs

- Hundreds of past projects in thermal engineering services for reference

- An extensive range of analytical software and thermal instrumentation

- Advanced numerical modelling steady state, transient, creep and Computational Fluid Dynamics (CFD) for thermo-fluid problems

- Practical advice, detailed reporting, scope and price fixed upfront, good value and fast service procedures

Thermal Expansion Analysis and Assessment – Our Approach

- A clear and deep understanding of thermal engineering theory and the issues resulting from thermal expansion

- Many collective decades of experience in thermal designs

- Hundreds of past projects in thermal engineering services for reference

- An extensive range of analytical software and thermal instrumentation

- Advanced numerical modelling steady state, transient, creep and Computational Fluid Dynamics (CFD) for thermo-fluid problems

- Practical advice, detailed reporting, scope and price fixed upfront, good value and fast service procedures

Benefits of Thermal Analysis and Assessment

Thermal engineering services offer low cost to benefit ratio – thermal stress and material changes can cause catastrophic failures, yet the science behind it is well established, and remedial measures are often simple and inexpensive

- Prevention – reduces potential down-time

- Reassurance – justify expenditure, improve safety credentials

- Unlock potential – identify extra life and capacity, operate and justify existing plant, plan improvements

- Diagnose – creep and fatigue are cumulative with few visual symptoms. Analysis allows plant to continue running despite partial failures, to find efficient fixes, and to inform redesign

Benefits of Thermal Analysis and Assessment

Thermal engineering services offer low cost to benefit ratio – thermal stress and material changes can cause catastrophic failures, yet the science behind it is well established, and remedial measures are often simple and inexpensive

- Prevention – reduces potential down-time

- Reassurance – justify expenditure, improve safety credentials

- Unlock potential – identify extra life and capacity, operate and justify existing plant, plan improvements

- Diagnose – creep and fatigue are cumulative with few visual symptoms. Analysis allows plant to continue running despite partial failures, to find efficient fixes, and to inform redesign

The Importance of Thermal Monitoring:

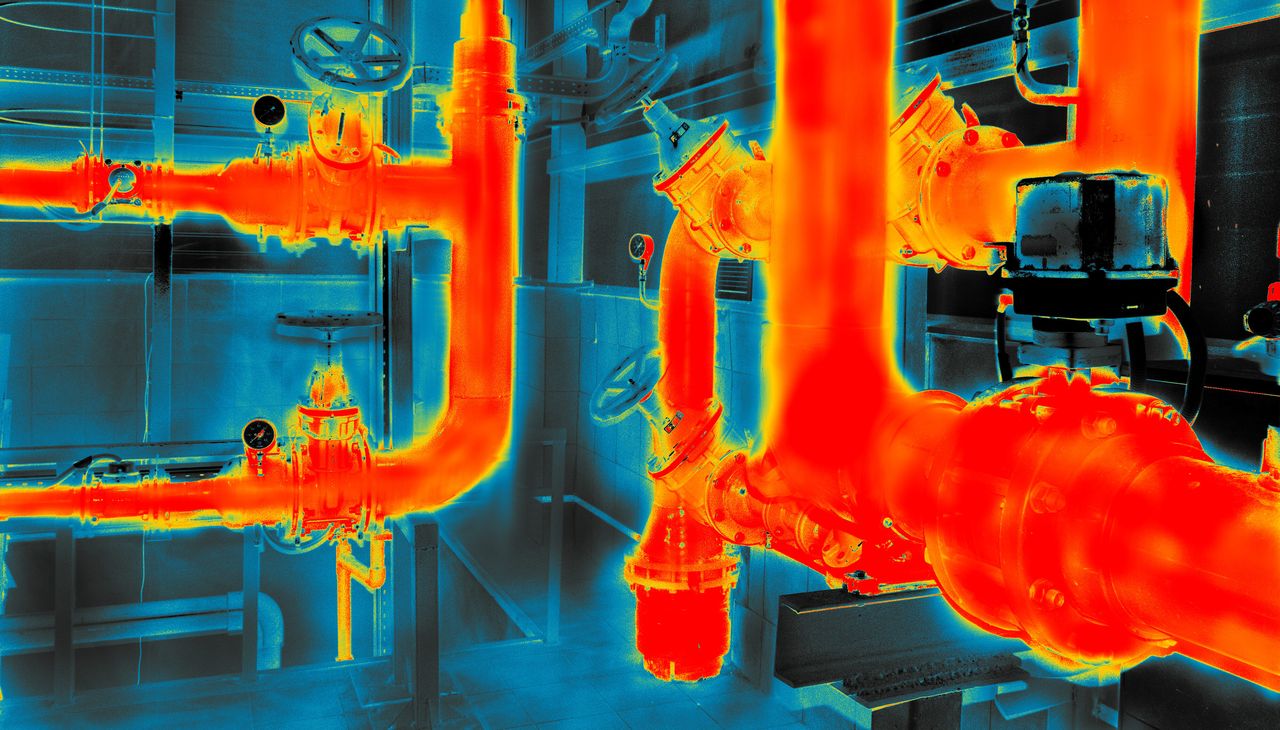

Material properties are defined by temperature, affecting their stiffness, toughness, work-hardening and ductility. A changing temperature causes most materials to expand or contract, and when constrained they can experience major thermal stress. High temperatures combined with stress can cause creep, weakened piping or causing contact and damage of moving parts.

We find that understanding thermal expansion, especially when conflicting materials are used, is consistently neglected by designers, and can catch them out at a very late stage. Heat costs money, and understanding how solids and fluids transfer thermal energy can be all that separates a plant from profitability. It could also be essential for sustaining or protecting a process.

The Importance of Thermal Monitoring:

Material properties are defined by temperature, affecting their stiffness, toughness, work-hardening and ductility. A changing temperature causes most materials to expand or contract, and when constrained they can experience major thermal stress. High temperatures combined with stress can cause creep, weakened piping or causing contact and damage of moving parts.

We find that understanding thermal expansion, especially when conflicting materials are used, is consistently neglected by designers, and can catch them out at a very late stage. Heat costs money, and understanding how solids and fluids transfer thermal energy can be all that separates a plant from profitability. It could also be essential for sustaining or protecting a process.

- Ageing plant – materials creep and fatigue, supports ‘bed-in’, plates corrode. Short term testing or long term remote monitoring and processing allows complex plant to operate safely.

- Uncertain geometry or operation – temperatures and stresses can be measured directly

- Validate analysis – mitigate uncertainty

- Ageing plant – materials creep and fatigue, supports ‘bed-in’, plates corrode. Short term testing or long term remote monitoring and processing allows complex plant to operate safely.

- Uncertain geometry or operation – temperatures and stresses can be measured directly

- Validate analysis – mitigate uncertainty

Latest case study

Latest case study