FEA Stress Analysis – Our Approach

Stress analysis is arguably the most fundamental application in engineering, spanning many eras, industries and ranges of complexity. It is a mature science with many practitioners and many available tools.

At DC White, we have decades of experience in solving stress-related issues for clients across many industries including;

Chemical, Nuclear and Process Plant, Aeronautical, Marine and Renewable Energy.

Stress Analysis – Our Approach

Stress analysis is arguably the most fundamental application in engineering, spanning many eras, industries and ranges of complexity. It is a mature science with many practitioners and many available tools.

At DC White, we have decades of experience in solving stress-related issues for clients across many industries including Chemical, Nuclear and Process Plant, Aeronautical, Marine and Renewable Energy.

Why Choose DC White

There are many reasons why clients use us again and again, but perhaps the most important is our ability to combine practical nous, gained from a wide range of real cases, with a high degree of academic insight and the latest powerful software tools.

Why Choose DC White

There are many reasons why clients use us again and again, but perhaps the most important is our ability to combine practical nous, gained from a wide range of real cases, with a high degree of academic insight and the latest powerful software tools.

The benefits of using DC White:

- We aim to understand the problem first, before we dive into the software

- We’ll give you practical, commercial advice

- We provide detailed reporting, with feedback of both the qualitative and quantitative

- Value for money: a fixed priced based on an agreed scope, so no surprises later

- Speed: rapid uptake, interim updates, disciplined quality procedures

The benefits of using us:

- We aim to understand the problem first, before we dive into the software

- We’ll give you practical, commercial advice

- We provide detailed reporting, with feedback of both the qualitative and quantitative

- Value for money: a fixed priced based on an agreed scope, so no surprises later

- Speed: rapid uptake, interim updates, disciplined quality procedures

Adherance to specialist code:

We commonly use BS, EuroCodes and ASME, and we also have the capability to follow a number of specialist codes, including:

- Pressure Vessels: PD5500 and ASME BPVC Section VIII

- Process piping: ASME B31 pressure piping, BS EN 13480

- Seismic: EuroCode 8 (EN1998)

- General Fatigue: BS7608

- Pumps in oil & gas industry: API 610 and NFPA 20

Adherance to specialist code:

We commonly use BS, EuroCodes and ASME, and we also have the capability to follow a number of specialist codes, including:

- Pressure Vessels: PD5500 and ASME BPVC Section VIII

- Process piping: ASME B31 pressure piping, BS EN 13480

- Seismic: EuroCode 8 (EN1998)

- General Fatigue: BS7608

- Pumps in oil & gas industry: API 610 and NFPA 20

DC White Engineering Consultants Toolkit

The most common tools are Finite Element packages which can be very powerful. However, we believe that you shouldn’t be given a calculator until you have learnt to count. The first analytical tools our engineers turn to are:

- A blank sheet of paper

- A clear and deep understanding of stress analysis theory

- Our many collective decades of experience

- Thousands of past projects for reference

- Engineering judgement, bringing together our whole team if necessary

DC White Engineering Consultants Toolkit

The most common tools are Finite Element packages which can be very powerful. However, we believe that you shouldn’t be given a calculator until you have learnt to count. The first analytical tools our engineers turn to are:

- A blank sheet of paper

- A clear and deep understanding of stress analysis theory

- Our many collective decades of experience

- Thousands of past projects for reference

- Engineering judgement, bringing together our whole team if necessary

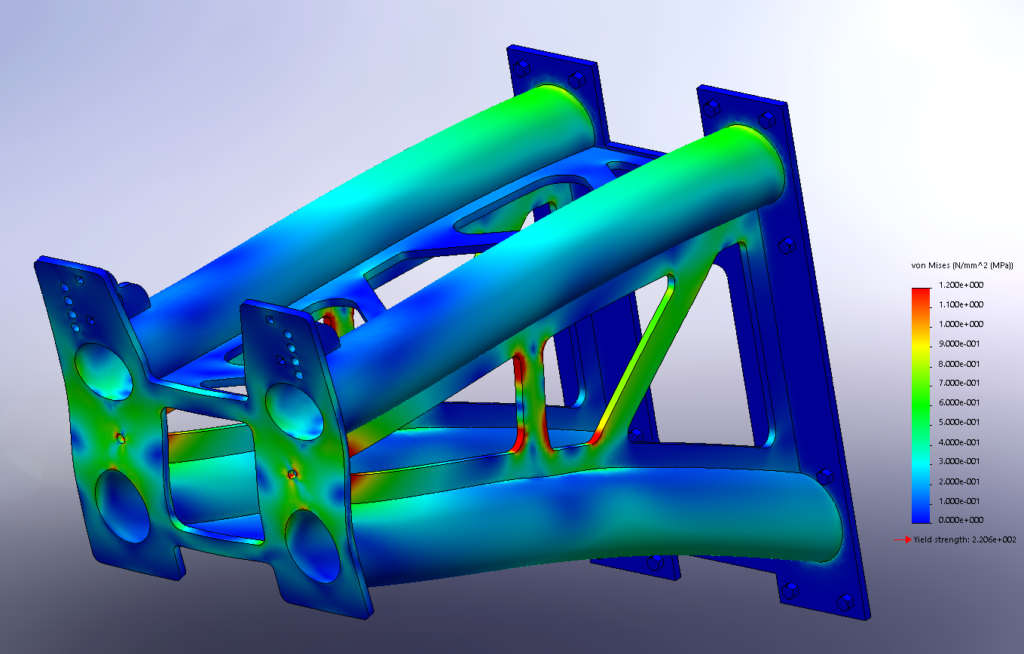

Powerful Software and Programming

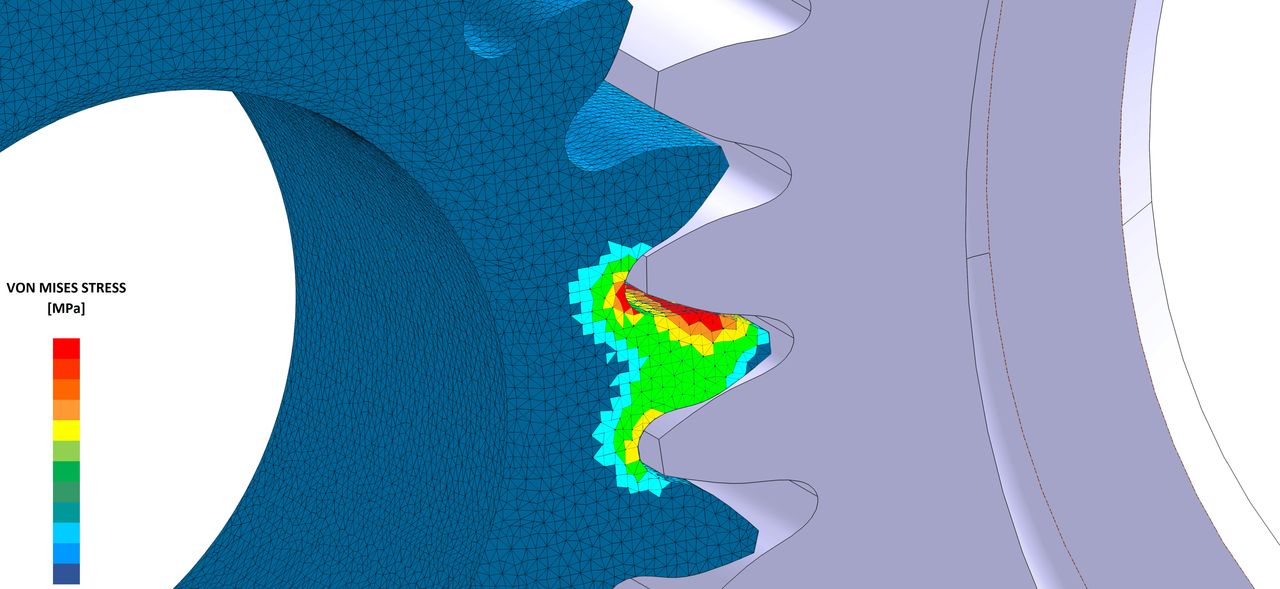

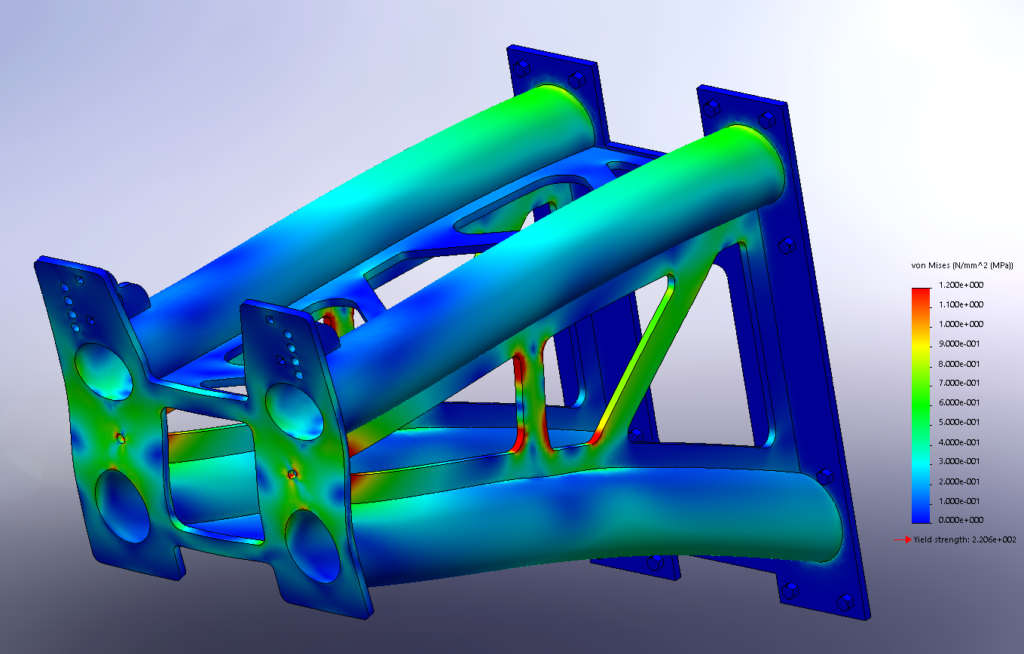

Once we have fully considered a problem, performed preliminary calculations and agreed a clear scope, we turn to our more advanced tools.

Hand calculations with MathCAD are a powerful, flexible and clear way of constructing an argument. For more complex systems we would then reach for our Finite Element software.

We have extensive collective experience with finite element stress analysis covering all the main engineering sectors across a wide range of physical scales and levels of complexity. See our case studies for more details.

Powerful Software and Programming

Once we have fully considered a problem, performed preliminary calculations and agreed a clear scope, we turn to our more advanced tools.

Hand calculations with MathCAD are a powerful, flexible and clear way of constructing an argument. For more complex systems we would then reach for our Finite Element software.

We have extensive collective experience with finite element stress analysis covering all the main engineering sectors across a wide range of physical scales and levels of complexity. See our case studies for more details.

Stress Analysis – Why is it important?

- Reduced outlay: identify expensive over- and under-design

- Prevention: reduces potential failures and down-time

- Reassurance: justify expenditure, improve safety credentials

- Unlock potential: identify extra capacity, operate with partial failure, plan improvements

- Diagnose: reduce down-time, find efficient fixes, inform redesign, prevent future failures

Stress Analysis – Why is it important?

- Reduced outlay: identify expensive over- and under-design

- Prevention: reduces potential failures and down-time

- Reassurance: justify expenditure, improve safety credentials

- Unlock potential: identify extra capacity, operate with partial failure, plan improvements

- Diagnose: reduce down-time, find efficient fixes, inform redesign, prevent future failures

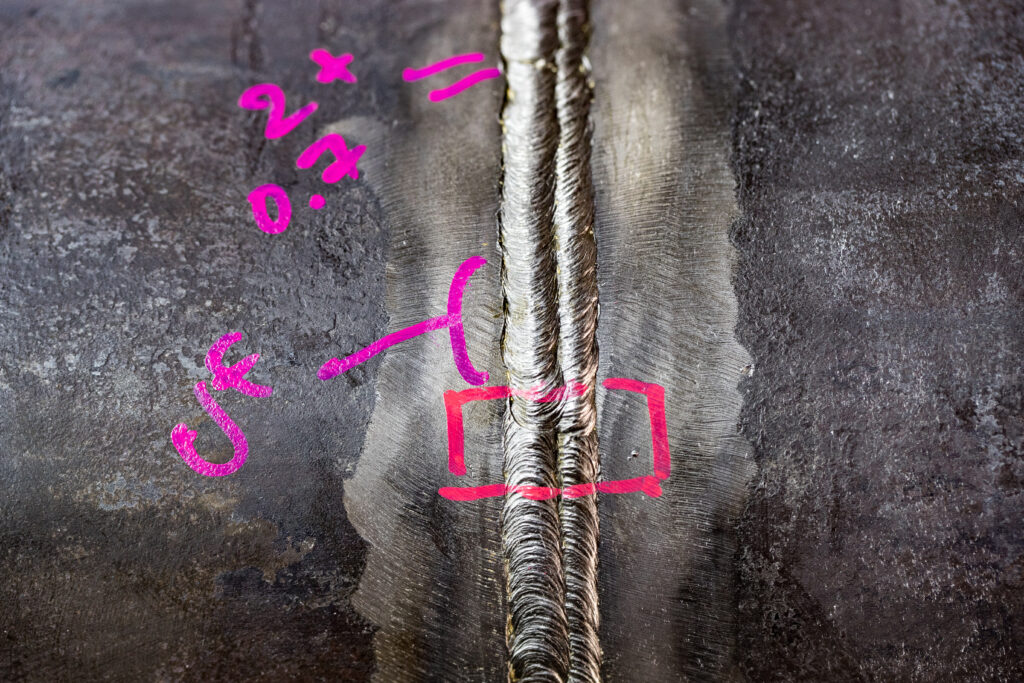

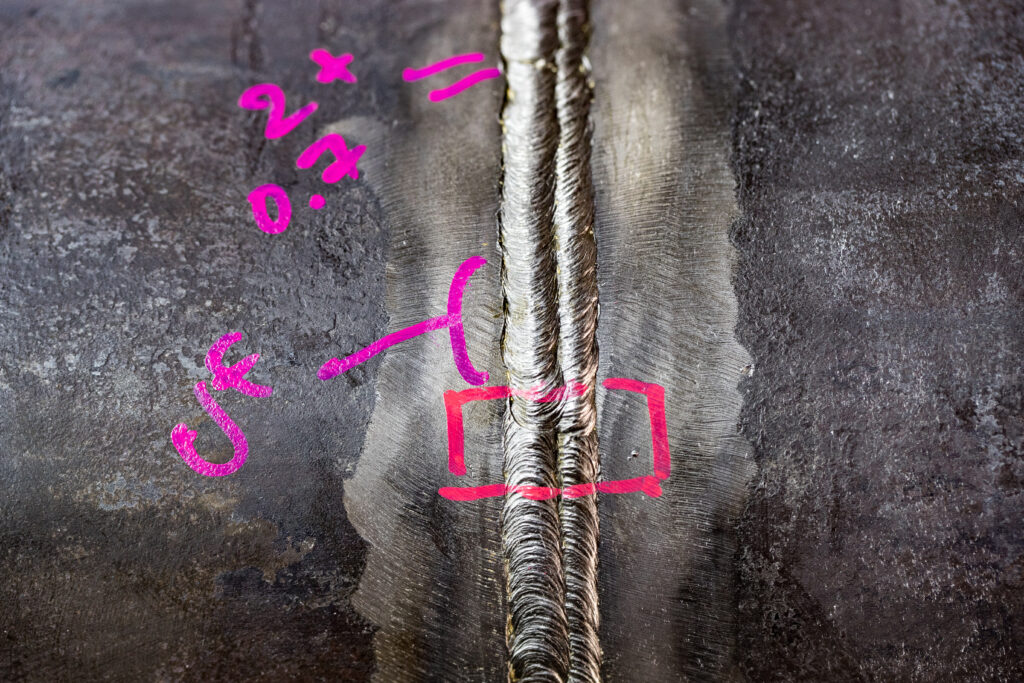

Latest case study

Latest case study