Case Studies: Failure Analysis |

Thermal analysis and NDT of crack in reactor vessel – Solvent Manufacturing

FEA Thermal Service Case Study DC White was approached by a large European solvent manufacturing company who had unwittingly been running one of their reactor vessels above its design temperature. The additional thermal load already placed on the vessel meant that it was removed from service and a site visit organised to carry out Non Destructive Testing (NDT) on the welds connecting the external limpet coils to [...]

Marine engine bearings failure analysis

DC White have recently been requested to carry out inspections of two large marine diesel bearings by a major fleet operator. The bearings failed prematurely and the fleet operator sought an independent opinion in order to assist in negotiations with the engine manufacturers. The first bearing was a main bearing and the second a crosshead bearing. The first had run for 15,000 hours and the second for [...]

Valves Seals and Gearboxes

Valves Transco experienced leakage problems on large 36" pipeline ball valves at a pressure reduction station. Valve leakage was investigated as part of a proposed legal action against the valve manufacturer. The leakage was found to be due to wear and compression set of the 'O' rings used to seal the valve seats. BP Clair Engineering Assessment of Sub Sea Isolation Valve Actuator Failure. Assisted [...]

Bearing Failures

Subsea Pump Bearing Investigation of failure on offshore sub-sea water winning pump bearings. Failure due to non-conservative design leading to high loads on bearing and an element of misalignment leading to fatigue of bearings. Subsea Pump Bearing Investigation of failure on offshore sub-sea water winning pump bearings. Failure due to non-conservative design leading to high loads on bearing and an [...]

Channel Tunnel Rail Link Piping Bracketry

Following our design work for the London Underground Jubilee line, we were asked to design the brackets that would hold the fire mains and drainage piping in the 43 kilometres of the Channel Tunnel Rail Link system. The brackets were required to support the self weight of the pipework as well as surge pressures. Surge Analysis Although the fire mains were permanently filled with water, [...]

Piping Safety Assessment at Major Chemical Plant

Background One of our major clients needed to extend the life of an ailing pipeline which had significant visible corrosion. It was commercially critical for the client to continue running the plant until the next scheduled maintenance period. Our job was to analyse the pipeline in its corroded condition and evaluate its on-going suitability for service. The Problem The line in question carried both toxic [...]

Exploding Wallpaper Stripper – Expert Witness

A water reservoir for a domestic wallpaper stripper exploded causing scalds to the operator. The unit appeared undamaged, so why should a seemingly faultless unit over-pressurize? Investigation into the nature of the unfortunate operator’s injuries showed that it resulted from a combination of cold weather and a failure to read the instructions – the steam pipe was full of ice preventing steam flow, so the operator held the [...]

Ladder collapse – Expert Witness

Engineer Expert Witness For Ladder Collapse This was a mystery with very little evidence, except that someone had injured themselves as they fell out of his attic trapdoor after a portable stepladder failed. The only evidence was a report by an HSE inspector who photographed the offending ladder and noted marks on a wall. By the time DC White were called in, the ladder had been destroyed and [...]

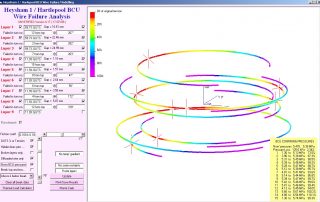

BCU Snapped Wire Software – Nuclear Plant

BCU Snapped Wire Software - Nuclear Plant We work on a wide and varied range of projects which means that sometimes there just isn’t a piece of software that can be pulled ‘off the shelf’ to provide the answer. At times like this we do not compromise with software. This piece of software was developed as part of a safety case for the nuclear industry. [...]

Heat Exchanger failure

Heat Exchanger failure - DC White were called in to investigate a calorifier (heat exchanger) in a cheese factory which had exploded during use. Fortunately there had been no injuries. The calorifier supplied hot water for cleaning dairy equipment but had exploded taking out the wall of the building in which it was sited. The unit had been recently checked and signed off by the licensing authorities. [...]